Free Will Brewing Company was founded by Dominic Capcec and John Stemler, officially licensed in January 2012. Their beginnings are as cliche as it comes. Two long-time friends brewed beer together on Sundays as a hobby from their successful full-time careers. Their hobby produced more beer than they could drink themselves so they started sharing with friends, and demand increased. They strapped together some funds and started the business. It took them 3 years to finally click, stating the first year was rough, and the 2nd year was rougher. But as I stand in their new 14-month project, a completely renovated triple the size brew house, I suspect things are clicking quite well.

Making Beer in the Old Basement

Currently Free Will keeps their malts in a cold dark portion of their basement brewery which used to be their old Tap Room. It’s important to keep temperature and humidity down to remove the threat of pests, specifically the “grain bug”. The new production facility upstairs will have a separate temperature and humidity controlled room just for grains. Free Will uses several varieties of malt – pale malts, or base malts, for the base of the beer, and several different varieties of roasted malts. A hand-made mill is used to grind the grains to crack them to expose the surface area and then hand wheel into the brewery.

In it’s most basic formula, starches within the grains are converted to sugars which yeasts feed on to produce alcohol. The milled grains go into a Mash Ton, basically a fancy name for a really big colander. The grain is mixed with very hot water, 138F-168F, which starts the chemical reaction of converting starch to sugar. The temperature of the water has a final effect on the beer, lower temperatures are more fermentable resulting in more dry and thinner body beer, while higher temperatures create more sweet and bigger bodied beers. It typically takes 45 minutes to 1 hour depending on how many cups of coffee he’s had in the morning.

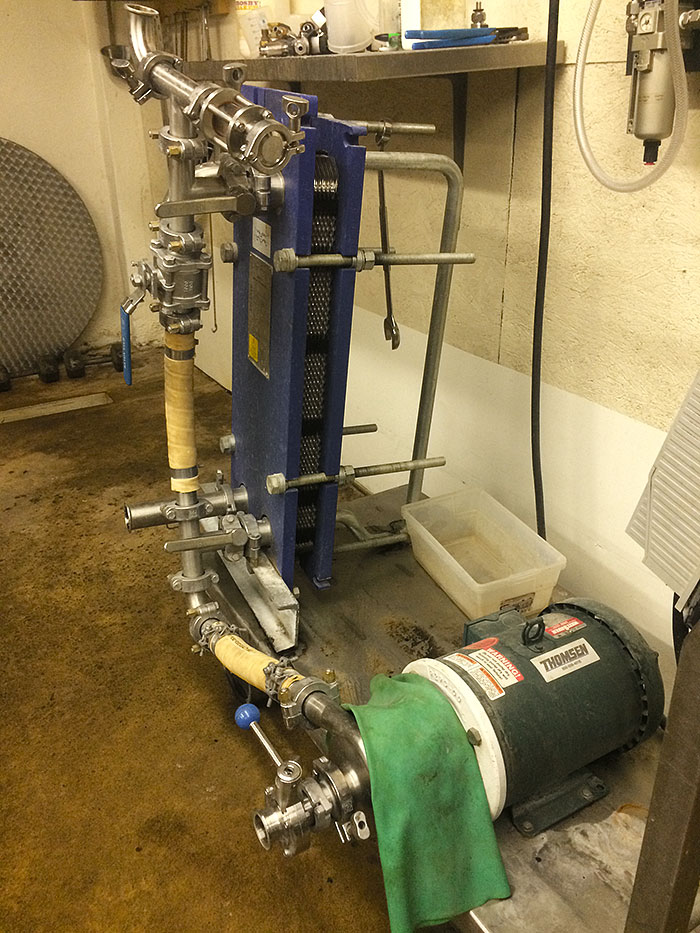

The Wort, or sugar water, is pumped out of the mash ton into a kettle. At this point very hot water is added for two reasons. First, you want to get the temperature over 168F to stop enzymatic activity which stops sugars from converting and to risk the sugars from changing the style of the beer. Secondly, since there is a lot of sugars, they need 250 gallons of wort in the kettle. Once in the kettle they will boil the wort and add the first dosage of hops. Boiling at this stage removes the chemical DMS, a vegetable taste associated with Rolling Rock, and for sanitation purposes to remove unwanted bacteria before adding yeast. During the boil, which lasts 60-90 minutes, hops are added at different times depending on which hop. Bitterness hops are added in the beginning of the boil as they are oil-based and take a long time to incorporate. Aroma and flavor hops are added in the last 10-15 minutes as they boil off very quickly.

In the fermentor, Ale or Lager yeast is added. Ales ferment at 68F above the surface of the liquid and works its way to the bottom. Lagers, on the other hand, ferment at 55F and work bottom up. Belgium beers ferment much hotter. High temperature beers like saisons and Belgiums ferment for 3 days. White beers ferment for 2 days, and a Kolsch can take up to 10 days with low temperatures. Higher temperature ferment creates esters and phenolics, wild fruits and spicy aromas especially in Belgiums and sours. Lagers are fermented at a lower temperature to keep those flavors away.

Free Will tries to use the natural carbonation when possible unless the beer is dry hopped as they will need to open the fermentation tank to add hops. Typically they use 20 pounds of dry hops in a 15 barrel batch. Ales can basically be bottled immediately while a Pilsner needs 6 weeks of cold storage. At this point, all is left is to carbonate, bottle, and package.

Sour Specialists

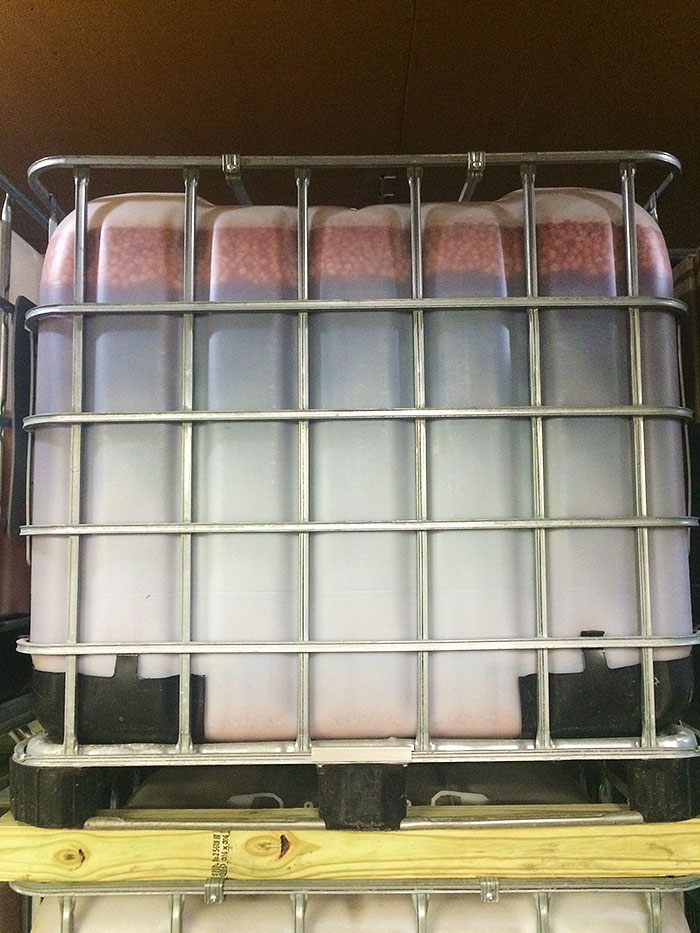

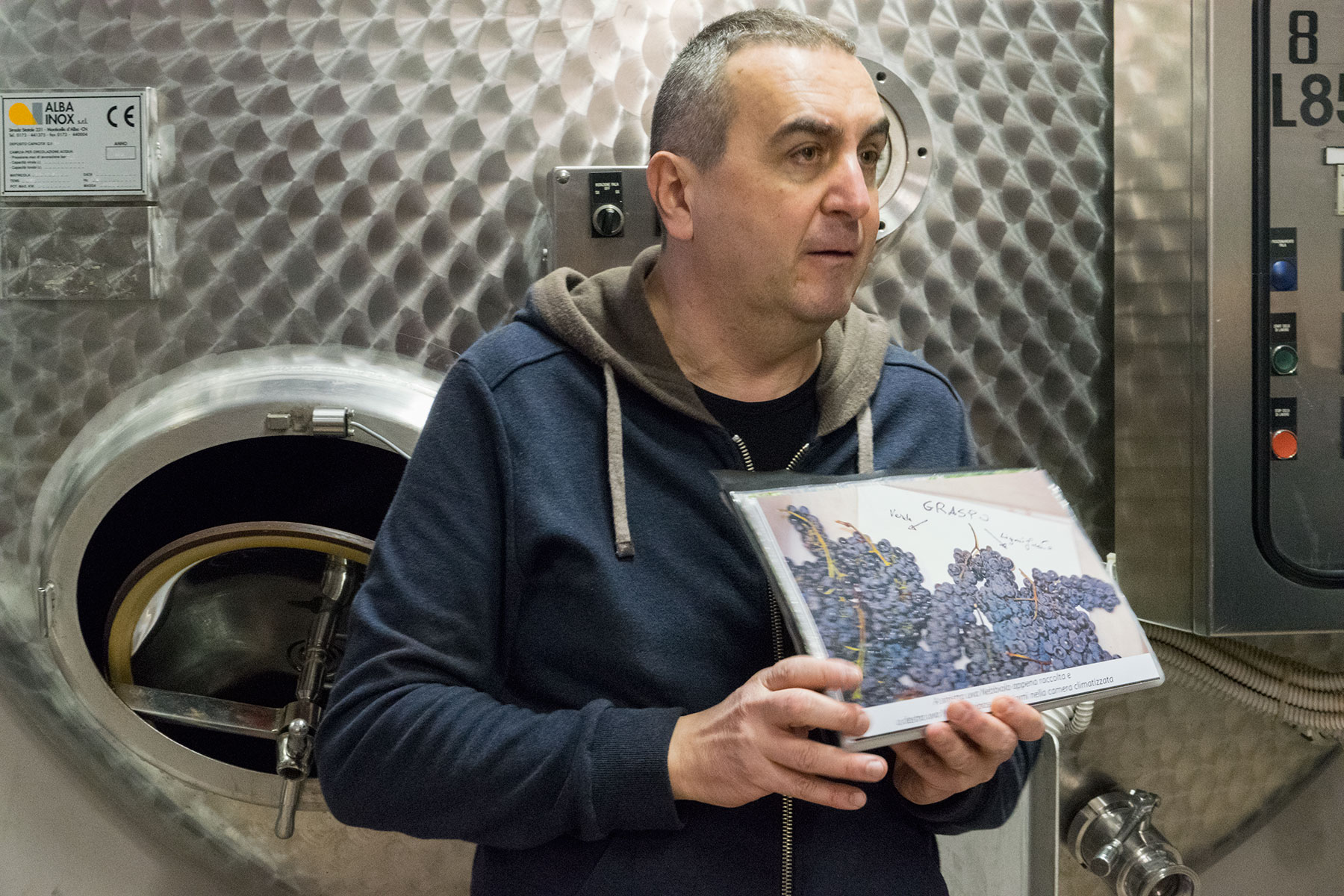

Once all the brewing equipment is moved to the new production facility upstairs, the temperatures will drop to upper 50s to mid 60s and humidity will lower a bit. These are perfect conditions for cellar oak-aging, cider, and sour production. As John explains, keeping all equipment and brewing segregated is the best way. The evil yeast strain brettanomyces is death for wine and beer, but essential for cider and sours. The goal is to create a house culture of yeast and bacteria that only the Free Will sour facility will have. Those yeasts and bacteria develop over time and cannot be replicated at another location.

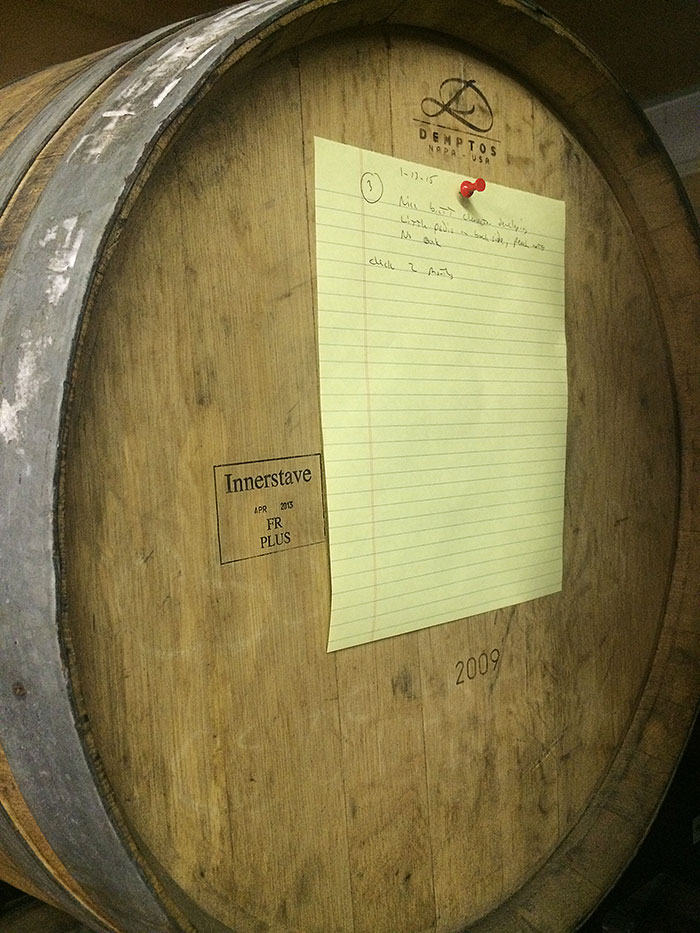

All containers and barrels are tasted very frequently, as it’s the only sure sign to know when the beer is completed. A strict tasting schedule is followed, as John says, after tasting a few barrels of sours your palate is destroyed. Barrels are kept until they literally fall apart. Bacterias continue to grow within each barrel producing differences between them all. Tasting notes are affixed to each. Once ready, they will all be blended for bottling.

The Future

Free Will Brewing now has a beautiful Tap Room with a main street entrance instead of the back-door basement dungeon tap room. Only a few months away from the new production facility, they will be able to supply 4 times the capacity compared to the basement facility. A new floor, the most considerable investment is the most important piece of equipment as it provides a clean and safe base. The old 9’10” head space of the basement is now allowing larger tanks and much less stress on the staff in the new high-ceiling.

On their third year, Free Will Brewing is the local brewery to watch and not just in the beer category. Their goal is to be the top sour beer producer within a 500 mile radius. After tasting their Kriek, Grape, and Key Lime lambics, I predict them to be one of the best in America.

Leave A Comment

You must be logged in to post a comment.